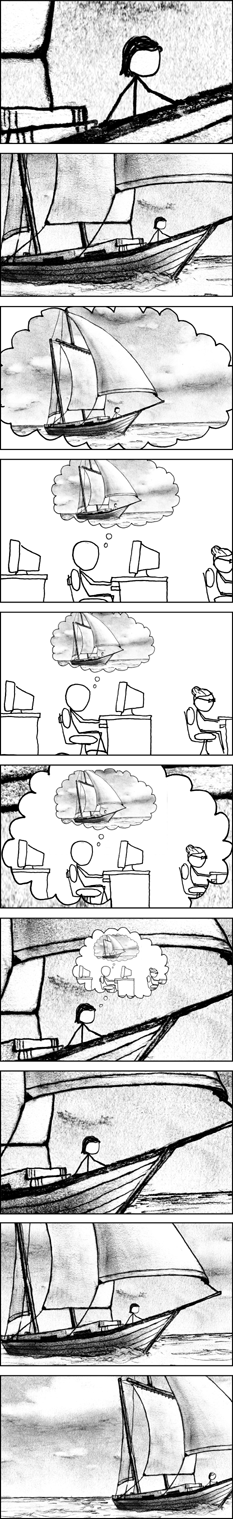

Monday, December 28, 2009

An expensive weekend, lessons learned: Running Aground

I typically have gotten nervous when it comes to taking Windsong out, rightfully so I might add. I am still a rookie with this boat and particularly the area it is in. Especially after breaking down the first time I took her out, I can't help get nervous. But this time I wasn't worried about the engine or anything particular about the boat. I've tuned the engine and performed all needed maintenance on it and it worked like a charm the last outing. But something was eating away inside me the few days leading up to Saturday and I didn't understand it. Some sort of premonition told me it we shouldn't go, but I ignored it and attributed it to my normal nerves. I should have listened.

So we took the 3 hour ride from St. Augustine to Inglis with my parents and their new Boston Terrier pup, Sawx. As we arrived to the dock my nerves had subsided and was ready for a good ride. I performed all the pre-ride checks on the boat and engine and felt pretty confident that Windsong would do well. Shortly after arriving we cast of the docklines and headed up the river towards the Gulf.

Things were going swell all the way up the river, so good in fact that I must have stopped paying much attention to where I was in the channel. We were motoring at roughly 6 knots only a few hundred yards before we reached the inlet when the boat SLAMMED into the river bottom and the bow reared up high out of the water. Thank goodness that no one was standing at the time or they would have gone flying off the boat or hard into something on it. I tried reversing and steering off, but we were stuck as stuck could be. The keel was resting hard on the bottom and would not budge. I sat there shocked and stunned and could not believe what had just happened. I took a moment to collect myself and made sure everyone was ok before I could think of what to do next. I considered kedging off the anchor but I had no way of getting it out far enough to be worthwhile. So I radioed on channel 16 for some help but recieved no ansewer even after a few tries. I eventually called the Coast Guard, which has a station on the river near the boat's dock, and told them my situation. They said that the only thing they could do is refer me to a towing company either Tow BoatUS or Sea Tow. I knew instantly that this was going to be a worse incident than I thought when they asked if I was a member to either. No, I'm not.

For somewhere around $150/year you can be a member of one of these tow companies and use their services when you need. I had considered getting a membership in particular for the overnight passage South that I need to take soon, just as a piece of mind in case things went wrong. But I never figured I would really need it until I finish working on the hard and start to sail a lot. I realized that was that a huge mistake as I spoke to the tow boat captain and got a quote to be hauled off the bottom. It would be $600 just for ungrounding the boat, plus $240/hour for the tow boat to come from Cyrstal River, about an hour and a half away ( you have to pay for their round trip). So the total quote for the haul was roughly $1,300. When he told me this all I could do was close my eyes, swallow my pride and gave him the ok to come get me. Bye Bye huge hunk of savings.

I considered my options while I waited for confirmation on my credit card and everything. We could wait for a boat to come by and hopefully lift us off with their wake. Unfortunately it was a very quiet day on the river and the only boats going by were small jon-boats with barely any wake. When a decent sized boat finally passed and sent wake our way, it only served to bounce the keel up and down on the bottom, not freeing us at all. Since we ran aground near high tide, it was apparent that waiting for the tide to come back in wasn't going to help much either. Plus, high tide wasn't until 8 p.m. and we had no way of getting back to the dock at night. Navigating the river without light was just out of the question.

So after a few minutes the tow company called me back and confirmed the operation and told me they would be here in an hour and a half. Great, by then the tide would be even lower and getting towed off the bottom would be even more difficult. So we sat waiting for that period of time, during which the air only seeming to get colder by the minute. I was so pissed that I made such a bonehead move that I could do little but stare at the distance in disdain for my bad piloting. But how would I have known this ledge was here? It wasn't marked on the charts or on my new GPS as most obstructions were in the river. As some fishing jon-boats rode by and we discussed what happened they all seemed to know that it got shallow there...local knowledge kicks ass if you have it, but I didn't.

I started to fear about the worst case scenario as the tide began to fall. On the port side, closest to shore, we could see that the water was getting shallower pretty quickly as the bottom was clearly visible in the murky water. On the other hand, the water to starboard was much deeper, if only we could get to it. The tow captain mentioned that if he didn't have success trying to pull us off since the tide was too low we would have to wait for it to come back in before trying again. Thus having to wait till all light was gone and we would be stranded there for the night. We were horribly unprepared to stay the night on the boat particularly due to the cold. We had food to last us, but no blankets and barely enough jackets as it was. I know my dad and I could tough it out if we had to, but my mom and the pup were with us and I would feel horrible if she had to go through that. So I thought if worse came to worse, the tow boat could take my parents and the dog back to the dock and I would stay with the boat overnight and wait for the morning high tide. Still, not something I was looking forward to as my first overnight stay on the boat. I would have been left with little more than sail covers as blankets to not freeze the whole night away.

The tow boat showed up right on queue and rafted up next to us. They sounded the area and found the water deep enough for my draft immediately to starboard, so not all hope was lost. But the water had gotten so shallow on the port side that if any of us put our weight over there the whole boat tilted on its keel at a hard angle. So we tied up the tow ropes and they started trying to pull the bow towards the center of the channel. It didn't work too well and only turned the boat a bit towards the channel, grinding the keel on the bottom. At one point the tow rope snapped after pulling so hard.

Things didn't look to bright at this point and the tow captain kept mentioning about possibly having to wait till high tide, my heart kept dropping as the effort kept failing. Eventually we tried a new tactic by using the main halyard attached to a second tow rope (leads to the top of the mast) to try to tilt the whole boat on its side, thus lifting the keel off the bottom as the tow line on the bow would pull the boat to the channel. After much grinding on the bottom and tilting the whole boat so far that the starboard rail was buried under water, it finally got loose off the bottom and we were pulled into deeper water. It took a long time and many different tries at different angles, but we eventually were pulled free. It was incredibly nerve wracking as it seemed like it would never work.

Relief rushed through me and I could do little more than thank God it was all over and we wouldn't have to stay there any longer. I made sure to ask the captain where else in the river I needed to be wary of, and he said that where we went aground was the worst spot. He has apparently pulled many a vessel off of the same ledge, one even a week previous. Good to know I thought, I will avoid that spot like the plague for now on.

The tow captain was friendly and also owns a sailboat. He told me to not get discouraged since pretty much everyone has made that mistake. Unfortunately I made the double mistake of not being a tow member and having to loose a big gob of cash. On top of it all, my brand new hand held VHF radio was clipped to my belt and sometime during the tow when the boat was heeled over and I was holding on for dear life, it got loose and went overboard. I was concentrating on the job at hand and none of us noticed it until we were motoring back to the dock. So the day got even more expensive.

It was a very bad day for me, but I was more relieved than bitter in the end and was glad we got back safely before dark. I felt pretty bad that we took the long drive out there to only have a bad experience, but my parents were positive the whole time and gave me good encouragement. It was a rough lesson learned, but one I was bound to learn one day nonetheless.

Tuesday, December 1, 2009

Project: Interior Woodwork

Windsong has a ton of wood in the cabin, mostly teak trim or veneer with teak & holly sole. The varnish and what appears to be stain on the wood has dulled and needs to be redone on most pieces. Some of the bulkheads are plywood with varnish but I would like to convert most of them to white or off-white by either painting or applying formica to the surfaces. I have begun taking wooden trim and other pieces off the boat to take home so that I can do the woodwork during the week.

As you can see here, the trim is dull and dirty, and needs re-working. I plan on taking it all off so that I can paint or re-surface the vertical surfaces with something white. The galley counter tops, nav table, and other areas with formica surfaces will also be redone.

In the v-berth on both sides and in the starboard side of the cabin there are long wooden slats decorating the sides. These will also be taken off to be refinished and so I can clean and paint the surfaces behind them, also hiding the chainplates.

You can see here the large bulkhead which I want to be white, along with most other vertical surfaces.

There are also some areas of damage that need to be attended to. The portside wood cabinets and adjacent bulkheads have suffered water damage and rot from a long term leak. Shown below is the galley and you can see the cabinets behind the stove where the problem is. The bottom and middle shelves of the cabinets need to be replaced, but the front piece of plywood and the trim are fine. The bulkhead on the right side of the picture has suffered wet rot in the area behind the cabinets and needs to be fixed or replaced somehow. That piping is for the heater and will be taken out.

Here is the rest of the length of that cabinet as it runs along the port side. The bulkhead at the end has suffered a lot of wet rot near the edge and needs to be fixed or replaced as well. You can't see it here, it is under the edge/behind the top bunk. I'll try to get better pictures of it so readers can help me with ideas on how to fix it.

Another area of concern is the anchor chain locker which has a lot of rot in it from some leaks around the bowsprit. Shown here is some of the damage, note that the cabinet door is completely torn apart.

Other damaged areas are mostly cabinet doors which can be replaced pretty easily. The sole has its share of damage, but is in fair condition overall. I do think I will be replacing parts of it, however, since I will be recondition the boat as a whole. Here is a big area of damage near the compionway steps:

As you can see I have a lot of work to do, but taking pieces home to start with has given me a first start. Working on the v-berth door has helped me develop my process for stripping the wood to be prepared for new finish. I will detail this in another post.

Wednesday, November 25, 2009

Finally changed the oil!

When I got to the boat I tried my newly rebuilt manual bilge pump and discovered that it had stopped working for some reason. I just replaced the major parts on it so I had no idea why it wouldn't work anymore. It takes two people to remove it, so I'll have to wait for a friend to come to troubleshoot it. Needless to say, I was pretty upset to find it not functioning once more. Last weekend it worked perfectly after we finished installing it. But now...nothing.

I also began to remove bungs and some trim around the boat to take home and begin more wood restoration. I figured that there is a lot of wood that needs to be stripped and varnished, better start now than later.

Then it was onto the engine: oil change and stuffing box tightening.

Pumping out the oil:

The oil change was smooth and uneventful. Getting it finally done was a happy occasion though. After the oil change I focused on the stuffing box. It was still leaking slowly, not as fast as when we stopped the engine a week ago. But still leaking more than it should. The problem is that the locking nut is stuck on its threads and wont budge. I can loosen up the packing nut (causing water to flow in fast), but I cannot tighten it anymore (needs to be tightened to stop water) because the locking nut is in the way. I used PB Blaster on the locking nut but that didn't do much to help. I didn't leave it on there for a long time before I tried, so maybe it has had some time to work and will be easier next time...but I'm not confident in it. Does anyone have any ideas on how the heck to get the locking nut loose?

Here is the whole unit:

Here it is with the packing nut loose, and you can see the locking nut stuck there:

Any help on that problem would be appreciated. I'll be heading home this weekend to see family for Thanksgiving. Then the following week I will come back out to the boat and begin preparations for the journey South. December might be tight to get her out of there due to busy weekends, but January should be favorable to finally move her.

Monday, November 16, 2009

Windsong's first sail, FLAWLESS!

On Saturday I wen't out to Inglis to see Windsong. I had three friends in tow and a list of things to accomplish. First off was to give the engine its oil change. I had replaced a few parts on the oil change pump and got it pumping water in a test run. But once we got to the boat the pump wouldn't suck out any oil and eventually burnt out. So now instead of repairing this thing I am going with advice of some other boat owners (readers of this blog, thanks!) and get a manual pump. So the oil change didn't happen, but that didn't stop us for the day. I also replaced the hose on the Whale Gusher manual bilge pump and was able to use it successfully for the first time. I love knowing that it works now, great sense of security especially since my primary electric bilge pump is still on the fritz. After the bilge pump we had to secure a leak on a water hose on the engine, then we were done with the needed chores of the day.

I had planned on taking her out and about in the river for the day, but with the encouragement of my friends and the weather cooperating we decided to take the trip out of the channel and hoist some sail. I was nervous because I still haven't upgraded a lot of the safety things (flares, fire extiguishers, etc.) that I wanted before we went out of the river, and the engine still makes me nervous, but we were feeling whimsical and went for it anyways. First off we had to turn the boat around in its narrow channel. We were able to to this using warps and a little knowledge from the PO, and now I have the confidence to be able to do this when we need! With the boat turned around and the engine warmed up we headed up the river.

The weather was absolutely perfect. Temperatures in the low-mid 70's, winds 10-15 knots from the West and the skies were completely clear. I figured that if things went bad, we could probably sail the entire way back up the river since the winds were pushing us back in. The ride up the river was uneventful and pretty. As we eventually passed the spot we broke down previously, a sense of confidence came about me as the engine remained in good pressure and temperature ranges and seemed to be trucking along perfectly. As we neared the river entrance I was became pretty nervous again at the prospect of going into open water. After we passed the inlet I started to feel good about it again and we navigated the 2 miles or so of channel markings to the green marker #1. At that marker we would be in deep enough water to go North or South on a sweet beam reach. Once we hit #1 the excitement was palatable as I instructed the crew on how to hoist and trim the sails. We lifted them up, turned North, shut off the engine and had our first moment of peace under sail with Windsong.

I could probably spend quite some time here describing the feeling of finally sailing with my boat. It has been a rough 5 months of ownership, barely having any fun time at all on the boat. I had little confidence in anything on it, and needed a successful ride to wash some of that away. Seeing the sails full, the rigging holding tight, and the wake behind us as we made a good 5.5-6 knots (we only have the gps to tell us speed) made so many fears go away. After trimming the sails and getting everything correctly situated, we ran North on a beam reach for about 2 miles before successfully taking South for another few miles. The feeling was intense as we all cracked open celebratory beers and took in the amazing weather and feeling of the silent (no engine) ride. Windsong sailed incredibly on the beam reach, as I expected her to. I was pretty impressed to find out how balanced she was with all of the sails up, barely needing to steer at all to keep her on course. She was moving so perfectly, and the weather was so brilliant that I considered going South for the whole day and night to get to Tarpon Springs and leave her there. But the journey will have to wait as we didn't have enough beer (or food) to last the trip.

After a while going South we tacked around again and started to aim towards the shore. We needed to get back in before the tide was too low and things got too shallow. We were able to run downwind on sail alone for most of the way back in the channel, but once the channel started to twist and turn we had to fire up the engine. We motorsailed all the way in the channel and a little bit into the river before we lowered all canvas and stowed the sails. Motoring back to the dock was pleasant, and we were able to dock and turn the boat around with ease.

Overall I could not have asked for a better first sail on my boat. The anticipation leading up to this was intense. I had mentally prepared for months for the day we took it out, and in the end everything went perfectly smooth. The only issue arising from the day is when I checked the engine over before we left and I noticed that the packing nut on the shaft seal was dripping frequently again. I tried to tighten it but it proved difficult without undoing the locking nut, something that has eluded me before. So I need to go up there this weekend and try to get that locking nut loose so I can tighten the packing nut. The unit as a whole needs servicing, particularly new packing in the nut. I'm not sure I have the confidence to do that myself just yet, but maybe if it is necessary I'll figure it out. With that fixed, the oil changed, safety items purchased, and some backup electronics...I can take Windsong down the coast to be hauled out for her re-build...and I will be very very very happy.

Here are the pictures from Saturday:

The yellow line is the route we took, for those truly interested it is from Chart #11408

View from the dock:

Do I look nervous?

Other boats along the river:

Taking a break from the helm to enjoy the deck

View of the power plant from the river

lol no worries here, can't go that fast.

Bad things have happened here...

I call this little beach the Redneck Riviera. It is usually packed with Florida's finest on weekends.

At the end of the river, beginning of the journey out to sea

First moments out of the river

Becoming a happy Cap'n

Beautiful on the water...

The smog around the power plants really stands out when you are at sea

Approaching marker #1. STOKED!!!!!

Shortly after....SAILS FULL!

So balanced, barely a need to steer

Taking it all in

Motorsailing back to the dock

Monday, October 19, 2009

Fuel Filters and some other stuff

I started with the oil change, figuring it to be an easy job to start the day. I was immediately stopped in my tracks because my oil change pump wasn't working correctly. It is a Jabsco oil change pump bucket with a small pump mounted on top just like this:

The pump would turn on, but it wouldn't suck anything through it. I played with it a bit but could never get it to pump. So I took it home to hopefully fix it this week, I have a feeling it needs a replacement impeller

So the oil change would have to wait. I went to the fuel filters next. Both filter changes were pretty straight forward, but I had a worry that I would need to bleed the fuel lines of air once done, a job I know would be more pain than it should be thanks to the engine being haunted. But after I changed the filters, the engine sputtered a bit for a few minutes and then ran just fine. Success! The primary filter was pretty dirty, I think my fuel tank is in serious need of cleaning. That might have to wait for the haul out though since I need to empty the tank for the truck haul anyways.

After the fuel filters we (Jenny and I) installed the manual bilge pump back in the cockpit without much hassle. But when I tried to run the hose down into the bilge, a crack on the hold hose showed itself and I accidentally broke the hose about 3 feet from its end, making it pretty useless. So I need to replace that hose, not much of an issue thank goodness...and the manual bilge pump will be in business!!!

I wanted to take the boat out for a ride afterward, but the PO wasn't around to give me some advice. The boat is parked at the dock the same way we came in when the engine overheated a few months ago. To turn the boat around in the narrow canal involves a method that I haven't been taught yet, so I was out of luck. Maybe next time I can actually ride Windsong up the river, and if God is really smiling on me...perhaps take her for a sail out in the Gulf!

There was one issue with the engine that needs to be resolved before I take it out, however. Along with the lingering oil change, water is coming out of a hose in the anti-siphon loop in the raw water circuit before where the water is injected into the exhaust. I think it is just a bad hose clamp, so I will have to experiment a bit to get that sealed tight and not leaking.

Thursday, October 8, 2009

"Confessions of a Long-Distance sailor" by Paul Lutus

I highly recommend the book. It chronicles his 3-year solo journey around the world in the late 80's. Here are some comments from the site:

[ in a review of "Maiden Voyage" by Tania Aebi posted at amazon.com ] I would recommend "Confessions of a Long Distance Sailor" by Paul Lutus instead of this book. It's written far better, has just as many aventures, is far more education in a worldly and sailing sense, and best of all, it's free.

— Chad LawieI'm about 55 pages into your book and wanted to tell you it is very good — charming, honest, insightful, a fine, fine story. You should really feel good about it.

— Sam Hill, author of five novels, http://www.samhillonline.comI have been touched on many levels by your wonderful story. Of course I knew nothing else about you other than the fact that you did what so many of us think we would love to do. I have interrupted my wife's quiet reverie countless times to read aloud a few words that you wrote. Apart from all your other wonderful accomplishments, thank you for this one.

— Tim SperryI just finished reading "Confessions." Thanks for writing it and making it available for free. I especially enjoyed all the philosophical and scientific tangents you go off on, while keeping everything somehow related to the sea. The last few days, I even had dreams of being on a boat.

If I have half as many interesting experiences as you've had by the time i'm your age, i'll be a happy man.

— William MacKayI just wanted to thank you for writing such a wonderful book about your circumnavigation ... marvelous!

— Marv PaulieI have started to read your "Confessions" ... I am amazed and inspired.

— Arlette Krampe

Monday, October 5, 2009

SUCCESS!

So the first thing we started with was the manual bilge pump. It is a Gusher Whale 10 MKIII pump:

Next we decided to tackle the engine. To catch you up, I had identified the problem in the engine to be the impeller of the raw water pump. The impeller had torn free of its hub and was not spinning, so no water came through the cooling system and the engine would overheat. After a lot of effort the past few weeks, I could not get the impeller out for the life of me. It should be a simple task, but the engineers at Yanmar thought it would be funny to put the impeller in the most impossible to reach location in the entire engine. Seriously...I don't think there is a worse location on the engine for a part that needs to be serviced. After about an hour of trying using various methods and a modified version of my impeller removal tool (I found a shorter bolt for the center bolt to use, see last post for why it failed), my Dad was able to get the impeller off the hub! We celebrated by getting lunch before attempting to install the new impeller and getting the water flowing through the engine again. The primary issue with this whole ordeal was that the impeller was stuck so hard on the hub because it had sat there idle for years. A relatively simple operation turned into a big project thanks to the location and condition of the impeller.

Once back from lunch, I spent some time trying to get the new impeller in the pump. It was a little tricky thanks to the yoga position you must be in to access the pump, and the impeller was liberally greased up thus making handling it difficult. Eventually I was able to get it in there, and hopefully it is greased up enough so removing it won't be much of an issue next time. After the impeller was installed and the cover plate put back on, I said my prayers and cranked the engine. I peered over the stern to see if water was flowing from the exhaust....nothing.

I go back into the engine room to investigate. First I opened the pump again to confirm that the impeller was actually turning, sure enough it was spinning just fine. After a few mintues of head scratching, I turned my attention to the plumbing leading to the pump from the through-hull. The first thing I noticed was that the refrigeration condensor, which is inline with the raw water circuit, had a large headspace of air in it, thus not letting the pump suck water up it and through the engine. I decided that since I will not be using the refrigerator for some time (it doesnt even work right now), I would bypass it alltogether and hook the engine pump direcly to the raw water strainer after the through-hull. After doing this we cranked the engine but no water was coming out still. Jeff thought of the bright idea to make sure all of the hoses and the strainer were completely filled with water so no air voids were in the system. I opened the strainer to find that the water level was below the entrance and exit hoses, and they were pretty dry themselves. So we filled up the system with water to prime it and cranked the engine again. I looked over the stern in anticipation, and after a few seconds of gugling water began to surge out of the exhaust!!!!

I haven't felt that relieved in a very long time, it was pure elation.

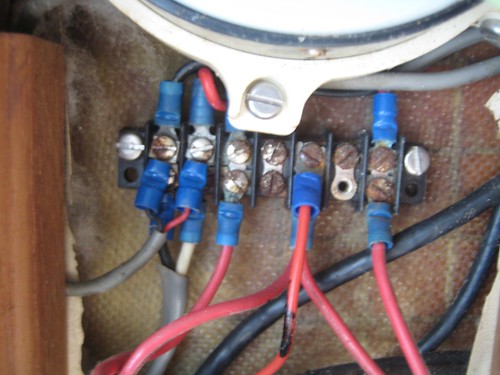

I haven't felt that relieved in a very long time, it was pure elation. We called it a day after that. To have fixed the engine problem after 2 months of weekend trips attempting to do it was such a great feeling. During all of this time Jeff had been working on replacing a corroded terminal strip, connections, fuses, and wires for all of the cockpit instruments. After replacing the bad connections, we were able to get power to all of the instruments. The wind and speed indicators seemed to be working, but the depth sounder still didn't turn on. At least we now know that it has something to do with the unit itself.

So my plan for this week is to order the parts to rebuild the manual bilge pump and fix it up. This weekend I will start what I wanted to do months ago, and do maintenance on the engine: oil and oil filter change, primary and secondary fuel filter change, and coolant change. Then I will hopefully have a fresh engine to take out for a ride up the river and eventually out to sea. I still have to troubleshoot the electric bilge pumps further. We think it is definitely a problem of electrical connections somewhere in the circuit, so an electrical cicuit testing session will be in order as well. If all else fails, I can still install the new pump I purchased for backup.

Big thanks to my Dad for bringing the know-how and tools to get all of this done. I am still an amature at all of this mechanical stuff, but knowing I have someone to turn to is extremely valuable. Also big thanks to Jeff for tackling the cockpit instrument job and aiding in solving the other problems.

For the first time in about two months (I've only owned the boat for 3), I am excited to get back to the boat instead of dreading it.

Wednesday, September 23, 2009

I suck at this

When I decided it was time to start taking the engine apart to remove the pump itself, I was stopped short by the alternator's pivot bolt being frozen in place. At the time I was trying to free it, I dropped one of the only sockets that fit that bolt down the bilge. I didn't have the tools or the skill to get the bolt undone, let alone remove the water pump.

So I think I am done trying to do this repair. It takes me 2 hours each way to get to and from the boat on a weekend, and when I accomplish nothing like this it just makes me so much more depressed. I think it is time to call the mechanic and get this thing fixed once and for all.

The only thing I was able to accomplish was stemming the fast drip of water from the packing nut on the stuffing box. With some effort I was able to tighten it up slightly to stop the water from dripping. So now hopefully the bilge doesn't fill up with water and sink the boat while I am away from it.

Wednesday, September 16, 2009

Weekend plan

ENGINE PROBLEM (raw water pump isn't working):

- PRAY that the shaft is spinning on the engine raw water pump. The impeller may have just come loose from its hub, but the shaft could still be spinning. I checked the impeller but left the rubber cap on the hub, so I don't know. If it is spinning....

- Use the newly purchased impeller removal tool to get the stubborn impeller out and replace. Should solve the problem, and I will be so so SO stoked, I would need some celebration beverages handy.

- If the shaft isn't spinning, we have problems. This means that I need to remove the pump itself to rebuild or replace, something I fear may be more difficult than it should be due to some terrible engineering on the engine. Refer to the picture below. First I would need to remove the compressor, and then the alternator to even access the hoses and bolts of the pump, since it is facing aft (what genius thought that up?). Then, though I can't speak with much authority on this since I can barely see through the parts as it is, two bolt heads holding the pump to the gearbox are behind part of the engine mount. There is hardly any clearance behind the bolt head, so I have no idea how they would come out without removing the engine mount arm that covers them. I am pretty sure removing that mount is WAY out of my skill range, and if it needs to be done I might be having to pay a lot of $$$$$ for a mechanic to do this. I assume that removing the mount would ruing the alignment of the engine, something I don't want to risk. Either paying a mechanic to come all the way out to the house it is at, or have the boat towed down the river to one of the small marinas. Hopefully I am wrong about the bolts and there is a clever way of removing them safely. But I'm not too certain that is the case.

- Diagnose the exact problem. I am pretty sure the diaphragm style pump is burnt out. I think the float switch got stuck, something in the wiring failed, or the hose got clogged and it burnt out. I need to figure out the problem to be certain.

- Try to get the Rule pump to work with the float switch (if the float switch works) for the diaphragm pump. The Rule pump has one, but it is set higher than the diaphragm float switch for emergency purposes.

- There is another diaphragm pump right next to the bilge diaphragm pump that serves some purpose in the fresh water pressure system. My thought is to replace the hoses and wiring on this one with the hoses of the bilge pump right next to it. This way I will have a working backup, and possibly get it to work with the float switch. In the picture below you can see the two pumps behind the battery bank, the bilge pump is on the right.

- Diagnose the problems with the manual bilge pump. Figure out if I can fix it or if I need to buy a new one.

Tuesday, September 8, 2009

Oh joy, more epic fail.

When we arrived I was welcomed by a whole new world of problems. I noticed that the indicator light on the bilge pump switch was on, but the pump wasn't running. I look into the sump below the engine and find that the bilge is very full of water. I play with the switches on the bilge pumps a bit and realize that only the wet pump is working, but the high and dry one is burned out. It seems to me that the float switches are busted or stuck, burning out the dry pump. The wet pump worked when flipped to manual, but not on automatic. And to top it off, I discovered the manual cockpit pump does not work and needs to be replaced or rebuilt. Since the boat is pretty darn leaky it is imperative that the pumps work. So now I have to rely on the PO to check the boat every few days to make sure she isn't sinking, and to flip the switch on the wet pump. I plan on installing another bilge pump when I go back, hopefully it isn't too much of a pain in the butt. This week I will be researching bilge pumps to figure out my approach.

After dealing with that disaster I finally got to the engine. For those catching up, the raw water circuit on the engine cooling system has failed and no water is pumping through or it is blocked. First, I went over the side of the boat and made sure the though hull wasn't blocked. I also blew out the hose coming from the through hull just in case. I then cranked the engine to make sure there were no leaky or collapsing hoses. I then removed the hose that comes out of the heat exchanger into the vented loop to see if water was coming out when the engine was cranked, nothing. So then I removed the cover of the pump to see the impeller, and when the engine was cranked I saw that the impeller was not spinning at all.

So the problem lies directly on the water pump and the impeller not spinning. From conversations with more knowledgeable types, this could mean that the pump shaft is broken. I guess my only option now is to take apart the water pump and figure it out from there? Any ideas?

I can't wait to actually enjoy this boat, because all it has been so far is a big pain in my rear.

Thursday, August 27, 2009

Monday, August 24, 2009

The Grand Plan version ???

understanding of both sailing and reality completely backwards.

Sailing is not an escape, but a return to and a confrontation of a reality

from which modern civilization is itself an escape.

For centuries, man suffered from the reality of an earth that was too dark

or too hot or too cold for his comfort, and to escape this he invented complex

systems of lighting, heating and air conditioning. Sailing rejects these and returns to

the old realities of dark and heat and cold.

Modern civilization has found radio, TV, movies, nightclubs and a huge variety

of mechanized entertainment to titillate our senses and help us escape from the

apparent boredom of the earth and the sun and wind and stars. Sailing returns

to these ancient realities.

-Robert Prisig

This weekend I took some time to catch the swell from hurricane Bill. I haven't surfed since my trip to Costa Rica two months ago, so it was great to be back in the water and have some fun. Saturday we went to New Smyrna Beach and enjoyed some of the most perfect Florida surf I have ever seen. They were not easy to get into, particularly because I had too small of a board for such large surf, but I was able to get many great rides. In the end, after about a hour of no waves, I caught one of the top 5 waves of my entire life, and easily the second biggest wave I have ever charged down (the largest being a wave from the latest Costa trip). Sunday we went to Cocoa but the swell had dropped and was doing nothing more than closing out in the shore break.

Now that I have had a two week break from the boat, I am ready to tackle it again. I haven't completely gotten my mind off of the boat as I have been continually researching, reading and doing more woodwork on the cabin door. I finally figured out how I am going to do the wood, and have settled on varnishing. Windsong deserves the great look of varnish, so I shall give it to her. I am experimenting on the door, and the first step is removing all of the old varnish. I have resulted to using a chemical peeler and have had some success getting the door down to the raw wood and color. Once I finish the whole door, I need to re-glue it back together (the door is in pieces) and then varnish.

As for the boat, there are currently a few phases that "The Grand Plan" (as I am calling it) will have to flow through:

- Get the boat out of Inglis

- Get it hauled out of water and decomissioned for shipment

- Ship it to Green Cove Springs Marina for work

- Launch and begin to sail the damn thing.

Aside from the engine, the most glaring need is the Depth Sounder. The current sounder is an old Datamarine:

It's current condition is...broken. I can't even turn it on, so I don't know if it is functioning beyond that. The first place I am looking to repair is the terminal block that the wiring for the sounder goes through. It is very corroded in places and the wire terminals for the sounder itself are very loose and seem trashed:

I hope by replacing the terminal block and the wire terminals the sounder will be able to turn on. If not, I have no idea what to do because the transducer is through-hull, so it isn't an easy swap out replacement. I may be forced to go down the coast out of Inglis without a depth sounder. And on the one of the biggest coasts of shoaling in Florida, I'm not stoked on that idea.

Aside from the engine and depth sounder, I feel she is ready to go. I replaced the running rigging, so sailing is going to be how I take her down. I do not want to rely on the engine for long, but I must to get in and out of the Gulf using power. Currently I have my eyes on Hernando Beach about 45 miles down the coast. It is very shallow in approach, but locals say that if you come in at a high tide (3ft +) there should be no problem. Well, the problem is that I need to get out of the Withlacoochie in Inglis at high tide as well. So I need to leave at high tide, make my way down the coast in time for the next high tide, all within daylight (!!??). Or I would need to somehow spend the night out in the Gulf and wait till the next day to try to enter the harbor. I have no idea if it is safe to anchor in the middle of the shoals of the Gulf, but there seems to be little other ways around this.

Of course, I could continue south and enter a harbor with less shoaling, such as Tarpon Springs. But I am still faced with an overnight journey. Let me interject that I have never done an overnight voyage before, let alone in strange waters, on a strange boat, with little instrumentation. You can start to see the task in front of me...yikes!

If anyone is willing to help me out with this issue, click here to see the chart of the area.

The channel to enter/exit the Withlaccochie at Inglis is at the very top of the chart. Hernando Beach is at 28°29′11″N 82°39′28″W. Tarpon Springs is at the very bottom.

There are a few marinas in Hernando Beach or Tarpon springs that can haul the boat and get it ready for shipment. Getting the boat ready for shipment will be a pain, but not as big of a pain as I see the previous tasks (engine fix, cruise down the coast). And once it is out of the water I will be able to finally see how much work I have before me. I am anticipating worst case scenario where I will have thousands of blisters (pox) and some other major repair jobs on the bottom. If there is one thing I am learning...expect (and prepare for) the worst, hope for the best. I will be very happy once it is out of the water though, because I can then get a realistic idea of what needs to be done and how long it will take before I can finally use Windsong in the way it deserves.

Once on land, it's time to ship to Green Cove. I am currently sold on Green Cove Springs Marina because they are hands down the cheapest of the yards I have looked at, they are in a location close to home (parent's house), and have a lot of friendly expertise and help around the yard. I will spend as long as I need on the hard there fixing all of the things that need to be fixed and getting as much refinishing done as I can. I would like to get the boat in the water sooner than later, so I need to prioritize the projects that need to be done on land.

I have a rough list of projects I know for sure that need to be done, but will save the list for another post.