Thursday, August 27, 2009

Monday, August 24, 2009

The Grand Plan version ???

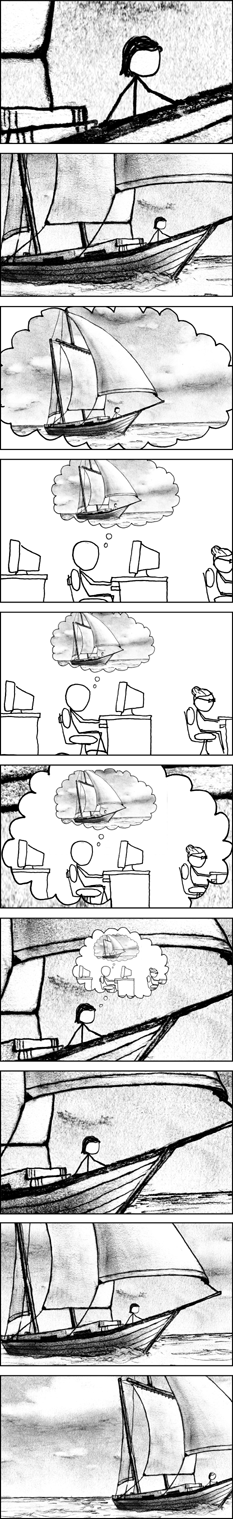

Those who see sailing as an escape from reality have got their

understanding of both sailing and reality completely backwards.

Sailing is not an escape, but a return to and a confrontation of a reality

from which modern civilization is itself an escape.

For centuries, man suffered from the reality of an earth that was too dark

or too hot or too cold for his comfort, and to escape this he invented complex

systems of lighting, heating and air conditioning. Sailing rejects these and returns to

the old realities of dark and heat and cold.

Modern civilization has found radio, TV, movies, nightclubs and a huge variety

of mechanized entertainment to titillate our senses and help us escape from the

apparent boredom of the earth and the sun and wind and stars. Sailing returns

to these ancient realities.

-Robert Prisig

This weekend I took some time to catch the swell from hurricane Bill. I haven't surfed since my trip to Costa Rica two months ago, so it was great to be back in the water and have some fun. Saturday we went to New Smyrna Beach and enjoyed some of the most perfect Florida surf I have ever seen. They were not easy to get into, particularly because I had too small of a board for such large surf, but I was able to get many great rides. In the end, after about a hour of no waves, I caught one of the top 5 waves of my entire life, and easily the second biggest wave I have ever charged down (the largest being a wave from the latest Costa trip). Sunday we went to Cocoa but the swell had dropped and was doing nothing more than closing out in the shore break.

Now that I have had a two week break from the boat, I am ready to tackle it again. I haven't completely gotten my mind off of the boat as I have been continually researching, reading and doing more woodwork on the cabin door. I finally figured out how I am going to do the wood, and have settled on varnishing. Windsong deserves the great look of varnish, so I shall give it to her. I am experimenting on the door, and the first step is removing all of the old varnish. I have resulted to using a chemical peeler and have had some success getting the door down to the raw wood and color. Once I finish the whole door, I need to re-glue it back together (the door is in pieces) and then varnish.

As for the boat, there are currently a few phases that "The Grand Plan" (as I am calling it) will have to flow through:

Aside from the engine, the most glaring need is the Depth Sounder. The current sounder is an old Datamarine:

It's current condition is...broken. I can't even turn it on, so I don't know if it is functioning beyond that. The first place I am looking to repair is the terminal block that the wiring for the sounder goes through. It is very corroded in places and the wire terminals for the sounder itself are very loose and seem trashed:

I hope by replacing the terminal block and the wire terminals the sounder will be able to turn on. If not, I have no idea what to do because the transducer is through-hull, so it isn't an easy swap out replacement. I may be forced to go down the coast out of Inglis without a depth sounder. And on the one of the biggest coasts of shoaling in Florida, I'm not stoked on that idea.

Aside from the engine and depth sounder, I feel she is ready to go. I replaced the running rigging, so sailing is going to be how I take her down. I do not want to rely on the engine for long, but I must to get in and out of the Gulf using power. Currently I have my eyes on Hernando Beach about 45 miles down the coast. It is very shallow in approach, but locals say that if you come in at a high tide (3ft +) there should be no problem. Well, the problem is that I need to get out of the Withlacoochie in Inglis at high tide as well. So I need to leave at high tide, make my way down the coast in time for the next high tide, all within daylight (!!??). Or I would need to somehow spend the night out in the Gulf and wait till the next day to try to enter the harbor. I have no idea if it is safe to anchor in the middle of the shoals of the Gulf, but there seems to be little other ways around this.

Of course, I could continue south and enter a harbor with less shoaling, such as Tarpon Springs. But I am still faced with an overnight journey. Let me interject that I have never done an overnight voyage before, let alone in strange waters, on a strange boat, with little instrumentation. You can start to see the task in front of me...yikes!

If anyone is willing to help me out with this issue, click here to see the chart of the area.

The channel to enter/exit the Withlaccochie at Inglis is at the very top of the chart. Hernando Beach is at 28°29′11″N 82°39′28″W. Tarpon Springs is at the very bottom.

There are a few marinas in Hernando Beach or Tarpon springs that can haul the boat and get it ready for shipment. Getting the boat ready for shipment will be a pain, but not as big of a pain as I see the previous tasks (engine fix, cruise down the coast). And once it is out of the water I will be able to finally see how much work I have before me. I am anticipating worst case scenario where I will have thousands of blisters (pox) and some other major repair jobs on the bottom. If there is one thing I am learning...expect (and prepare for) the worst, hope for the best. I will be very happy once it is out of the water though, because I can then get a realistic idea of what needs to be done and how long it will take before I can finally use Windsong in the way it deserves.

Once on land, it's time to ship to Green Cove. I am currently sold on Green Cove Springs Marina because they are hands down the cheapest of the yards I have looked at, they are in a location close to home (parent's house), and have a lot of friendly expertise and help around the yard. I will spend as long as I need on the hard there fixing all of the things that need to be fixed and getting as much refinishing done as I can. I would like to get the boat in the water sooner than later, so I need to prioritize the projects that need to be done on land.

I have a rough list of projects I know for sure that need to be done, but will save the list for another post.

understanding of both sailing and reality completely backwards.

Sailing is not an escape, but a return to and a confrontation of a reality

from which modern civilization is itself an escape.

For centuries, man suffered from the reality of an earth that was too dark

or too hot or too cold for his comfort, and to escape this he invented complex

systems of lighting, heating and air conditioning. Sailing rejects these and returns to

the old realities of dark and heat and cold.

Modern civilization has found radio, TV, movies, nightclubs and a huge variety

of mechanized entertainment to titillate our senses and help us escape from the

apparent boredom of the earth and the sun and wind and stars. Sailing returns

to these ancient realities.

-Robert Prisig

This weekend I took some time to catch the swell from hurricane Bill. I haven't surfed since my trip to Costa Rica two months ago, so it was great to be back in the water and have some fun. Saturday we went to New Smyrna Beach and enjoyed some of the most perfect Florida surf I have ever seen. They were not easy to get into, particularly because I had too small of a board for such large surf, but I was able to get many great rides. In the end, after about a hour of no waves, I caught one of the top 5 waves of my entire life, and easily the second biggest wave I have ever charged down (the largest being a wave from the latest Costa trip). Sunday we went to Cocoa but the swell had dropped and was doing nothing more than closing out in the shore break.

Now that I have had a two week break from the boat, I am ready to tackle it again. I haven't completely gotten my mind off of the boat as I have been continually researching, reading and doing more woodwork on the cabin door. I finally figured out how I am going to do the wood, and have settled on varnishing. Windsong deserves the great look of varnish, so I shall give it to her. I am experimenting on the door, and the first step is removing all of the old varnish. I have resulted to using a chemical peeler and have had some success getting the door down to the raw wood and color. Once I finish the whole door, I need to re-glue it back together (the door is in pieces) and then varnish.

As for the boat, there are currently a few phases that "The Grand Plan" (as I am calling it) will have to flow through:

- Get the boat out of Inglis

- Get it hauled out of water and decomissioned for shipment

- Ship it to Green Cove Springs Marina for work

- Launch and begin to sail the damn thing.

Aside from the engine, the most glaring need is the Depth Sounder. The current sounder is an old Datamarine:

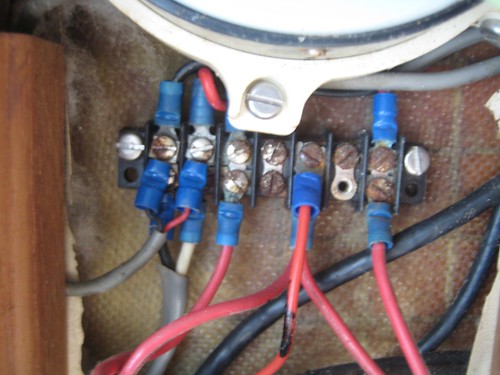

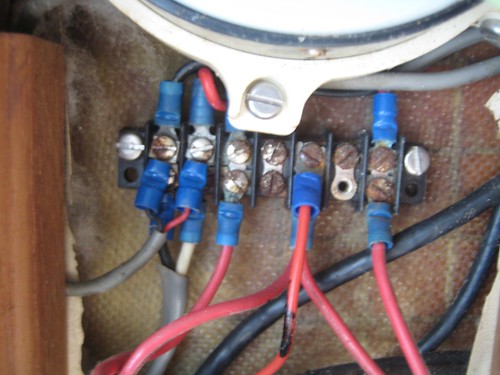

It's current condition is...broken. I can't even turn it on, so I don't know if it is functioning beyond that. The first place I am looking to repair is the terminal block that the wiring for the sounder goes through. It is very corroded in places and the wire terminals for the sounder itself are very loose and seem trashed:

I hope by replacing the terminal block and the wire terminals the sounder will be able to turn on. If not, I have no idea what to do because the transducer is through-hull, so it isn't an easy swap out replacement. I may be forced to go down the coast out of Inglis without a depth sounder. And on the one of the biggest coasts of shoaling in Florida, I'm not stoked on that idea.

Aside from the engine and depth sounder, I feel she is ready to go. I replaced the running rigging, so sailing is going to be how I take her down. I do not want to rely on the engine for long, but I must to get in and out of the Gulf using power. Currently I have my eyes on Hernando Beach about 45 miles down the coast. It is very shallow in approach, but locals say that if you come in at a high tide (3ft +) there should be no problem. Well, the problem is that I need to get out of the Withlacoochie in Inglis at high tide as well. So I need to leave at high tide, make my way down the coast in time for the next high tide, all within daylight (!!??). Or I would need to somehow spend the night out in the Gulf and wait till the next day to try to enter the harbor. I have no idea if it is safe to anchor in the middle of the shoals of the Gulf, but there seems to be little other ways around this.

Of course, I could continue south and enter a harbor with less shoaling, such as Tarpon Springs. But I am still faced with an overnight journey. Let me interject that I have never done an overnight voyage before, let alone in strange waters, on a strange boat, with little instrumentation. You can start to see the task in front of me...yikes!

If anyone is willing to help me out with this issue, click here to see the chart of the area.

The channel to enter/exit the Withlaccochie at Inglis is at the very top of the chart. Hernando Beach is at 28°29′11″N 82°39′28″W. Tarpon Springs is at the very bottom.

There are a few marinas in Hernando Beach or Tarpon springs that can haul the boat and get it ready for shipment. Getting the boat ready for shipment will be a pain, but not as big of a pain as I see the previous tasks (engine fix, cruise down the coast). And once it is out of the water I will be able to finally see how much work I have before me. I am anticipating worst case scenario where I will have thousands of blisters (pox) and some other major repair jobs on the bottom. If there is one thing I am learning...expect (and prepare for) the worst, hope for the best. I will be very happy once it is out of the water though, because I can then get a realistic idea of what needs to be done and how long it will take before I can finally use Windsong in the way it deserves.

Once on land, it's time to ship to Green Cove. I am currently sold on Green Cove Springs Marina because they are hands down the cheapest of the yards I have looked at, they are in a location close to home (parent's house), and have a lot of friendly expertise and help around the yard. I will spend as long as I need on the hard there fixing all of the things that need to be fixed and getting as much refinishing done as I can. I would like to get the boat in the water sooner than later, so I need to prioritize the projects that need to be done on land.

I have a rough list of projects I know for sure that need to be done, but will save the list for another post.

Labels:

Engine,

Inglis Weekends,

Projects,

Random,

The Grand Plan

Wednesday, August 12, 2009

Contemplation of issues.

This previous weekend I had intended on staying on the boat and working on this and that, particularly the engine problem. I came alone on Saturday, expecting to have my Dad come down to help on Sunday. When I arrived I kicked around the boat for a bit before finishing work on the anchor chain. I may have mentioned this previously, but the anchor chain is in decent condition with the exception of two corroded links. I used some bolt cutters to remove the two bad links and replaced them with a connector link secured with seizing wire. I needed to feel good about something before I started the engine, so the anchor project was just a spring board for the day. But hey, I initially thought I would need to buy a whole new anchor rode, but I cut a potential $500+ job to under $10. Success!

So after the anchor chain fix I went to the engine room to begin my assessment. I received a lot of good advice from the forum posts I made and was ready to put the advice to good use. I took a moment to survey the area and the water pump. In order to reach the water pump, I would need to remove the refrigerator compressor and the alternator to have enough room to remove the pump. After much thought, I concluded that I would definitely need some help with the process and would wait for my Dad to show up. As I was getting out of the engine room I knocked over my one and only lamp for the boat, thus making it a potentially dark and dreary night. On top of that my only entertainment, the internet, was not working for some reason. I decided to call it a day soon after that and not bother staying. I also concluded that it would be a good idea to talk to the PO (previous owner) about the issue since he might have a solution. He has been out of the country for a few weeks and wont be back until later next week. Once I talk to him and get any info he has, I will get pops down and we will tear into the project.

On that boat trip I thought a lot about the work to come on Windsong. Lemme tell you...its a lot. I have started to feel the overwhelming pressure of the project before me, and I'd be a liar if I told you I haven't had a mental breakdown over the monumental task before me. I have previously had nothing but excitement for all of it, but since I got cut back at work the financial burden will start to hurt me soon. I spent so long getting out of debt and saving for this, to have the job taken back like this hurts a lot. But I'm not broke yet, and I have a little while before the paychecks start to shrink. I am searching for some positive motivation to keep my head up, but the one thing that I know would make it better is to be able to be near the boat. Driving 2+ hours every week for a potentially ruined work day from lack of preparation is becoming tiring already. My original plan was to get the boat safe and take it all the way down to Port Charlotte and work on the boat on the hard there, a 3+ hour drive from where I live in Orlando. I decided this previous weekend that there is no way that will work.

So the new plan is something I am pretty excited about, except the cost. I want to find a place to haul the boat out as close as possible to Inglis, then get it shipped to either Orlando, the DIY marina in Titusville or Green Cove Springs. If I bring it to Orlando, I can have it in a work yard very cheaply on a monthly basis, and I would be able to work on it every day if I so chose. The downside of keeping it in Orlando is that I would need it shipped again to the coast once I am done working on it, and I would need to buy things like jack stands to keep it on. The idea came from this guy who is currently doing a major restoration to his yacht in Orlando:

If I take it to Titusville, I would pay a bit more per month for their lot, but would have things like jack stands and would be surrounded by people who know what they are doing. Depending on prices, I am also considering Green Cove Springs Marina which has a great DIY yard and a community of old salts willing to give out knowledge. Though it would be a 2 hour drive, it is close to my parents so I'd at least have a place to stay. So I have to think this out, but I am in the process of posting this dilemma on different forums to get some more knowledgeable advice.

So after the anchor chain fix I went to the engine room to begin my assessment. I received a lot of good advice from the forum posts I made and was ready to put the advice to good use. I took a moment to survey the area and the water pump. In order to reach the water pump, I would need to remove the refrigerator compressor and the alternator to have enough room to remove the pump. After much thought, I concluded that I would definitely need some help with the process and would wait for my Dad to show up. As I was getting out of the engine room I knocked over my one and only lamp for the boat, thus making it a potentially dark and dreary night. On top of that my only entertainment, the internet, was not working for some reason. I decided to call it a day soon after that and not bother staying. I also concluded that it would be a good idea to talk to the PO (previous owner) about the issue since he might have a solution. He has been out of the country for a few weeks and wont be back until later next week. Once I talk to him and get any info he has, I will get pops down and we will tear into the project.

On that boat trip I thought a lot about the work to come on Windsong. Lemme tell you...its a lot. I have started to feel the overwhelming pressure of the project before me, and I'd be a liar if I told you I haven't had a mental breakdown over the monumental task before me. I have previously had nothing but excitement for all of it, but since I got cut back at work the financial burden will start to hurt me soon. I spent so long getting out of debt and saving for this, to have the job taken back like this hurts a lot. But I'm not broke yet, and I have a little while before the paychecks start to shrink. I am searching for some positive motivation to keep my head up, but the one thing that I know would make it better is to be able to be near the boat. Driving 2+ hours every week for a potentially ruined work day from lack of preparation is becoming tiring already. My original plan was to get the boat safe and take it all the way down to Port Charlotte and work on the boat on the hard there, a 3+ hour drive from where I live in Orlando. I decided this previous weekend that there is no way that will work.

So the new plan is something I am pretty excited about, except the cost. I want to find a place to haul the boat out as close as possible to Inglis, then get it shipped to either Orlando, the DIY marina in Titusville or Green Cove Springs. If I bring it to Orlando, I can have it in a work yard very cheaply on a monthly basis, and I would be able to work on it every day if I so chose. The downside of keeping it in Orlando is that I would need it shipped again to the coast once I am done working on it, and I would need to buy things like jack stands to keep it on. The idea came from this guy who is currently doing a major restoration to his yacht in Orlando:

If I take it to Titusville, I would pay a bit more per month for their lot, but would have things like jack stands and would be surrounded by people who know what they are doing. Depending on prices, I am also considering Green Cove Springs Marina which has a great DIY yard and a community of old salts willing to give out knowledge. Though it would be a 2 hour drive, it is close to my parents so I'd at least have a place to stay. So I have to think this out, but I am in the process of posting this dilemma on different forums to get some more knowledgeable advice.

Labels:

Engine,

Inglis Weekends,

Projects,

Random

Monday, August 3, 2009

Engine still overheats and bad news from work.

This weekend didn't go too well. Well, it didn't start well either. On Friday I was cut to part-time at work, effectively reducing my salary by 20%. Thats all the money I had to save and spend on the boat. I will be just making the payments and insurance now, but money for refitting is severely limited now. I've said many times that as long as my job holds up, I should be on target for everything boat related. This will be a set back for sure, but temporary at most.

As for this weekend on the boat, I'll let this post I made on Sailnet describe it. I am stuck on the engine problem still:

http://www.sailnet.com/forums/diesel-engine-forum/56761-cooling-system-problems-need-some-help.html

As for this weekend on the boat, I'll let this post I made on Sailnet describe it. I am stuck on the engine problem still:

http://www.sailnet.com/forums/diesel-engine-forum/56761-cooling-system-problems-need-some-help.html

I recently purchased a 1975 Downeaster 38' Cutter, re-powered in 1994 with a Yanmar 4JH2E. It only has about 900 hours on the engine, but has been sitting unused for a few years now. I live in Orlando, FL but the boat is in Inglis, FL near Crystal River in the Big Bend area at the sellers dock. He is being kind enough to let me keep it there until I get it in shape to take it elsewhere. So I am limited to making weekend trips up there for now.

When we did the sea trial, the engine performed just fine. We ran it up and down the river for almost 3 hours with no problems at all. I had not taken her out since then (about a month) and have just been doing a lot of cleaning and work replacing the running rigging. Two weekends ago I decided it was time to take her out on the river (its on the Withlacoochee River) and show some friends a good time. Before we went out, I checked all fluids, cleaned out the raw water strainer and topped off the coolant. I noticed there was no rubber gasket or anything on the cap of the raw water strainer, just a metal plate. I didnt think much of it at the time, but now I wonder if there should be one.

The engine ran just fine for about an hour up the river. At one point, I revved it up to 2,800 rpms to see how it responded at cruising speed. Soon after my heart sank as I noticed steam (of course I first thought it was smoke and we were burning down) gushing out of the engine room. I quickly shut it off and had to release the anchor for the first time on the boat (something I needed to learn soon, but in less stressful circumstances).

The cap on the expansion tank for the cooling system had popped off and the cooling water was steaming everywhere. I also noticed that the air silencer had popped off and was hanging by a hose. I had checked it before we left and may have not secured it correctly. So I topped off lost coolant and let the engine rest for a while.

It was getting dark soon and we needed to get back. The engine cranked up just fine but after a short while the temperature was running high. Right before we got to the dock the cap on the expansion tank popped off and once again steam goes everywhere.

We had to go back to Orlando for the week so I did some research and stupidly realized that I didn't check if water was flowing out of the exhaust at all. I had also remembered that the belt was pretty loose, so those were first on the list to check when I came back. I would make sure to double check how I closed the water strainer.

So I go back to the boat this previous weekend. I tighten the belt after much hassle and checked to make sure the raw water strainer is tightly sealed. I then started the engine and first checked to see if any water was coming through the exhaust....none. So my guess is that the problem lies in the raw water circuit somewhere, correct?

I planned on checking and replacing the impeller, of which the previous owner already had a new spare. I soon realized that the impeller is in a hellish place where I can only fit one arm with barely enough room to move a tool. Removing the cover plate for the impeller was tricky, but I did it without loosing my cool. Then I realized that I would not be able to take the impeller out with any ease. I hoped to use the 2 screwdriver method to pry it out, but there was no way I could get two of them in there. I spent the majority of my day getting frustratedover figuring out how to get the impeller out, and didn't get much else done.

The only other thing I checked was to make sure there was nothing blocking the through-hull. I popped the inlet hose from the raw water strainer and was able to suck water through, so that was clear at least.

After leaving my dad asked if I checked to make sure the impeller was even turning after the engine was on...no, I didn't check.

The boat is old, but the engine is the one thing I was happy to have working fine. This completely has left me in the dumps emotionally, and then to cap it off I got cut to part-time at work this week amidst a bunch of lay-offs. Im lucky I still have the job, but loosing 20% of my salary takes away the extra money I was using each month to get the boat in shape.

So that is where I am. What steps should I take this weekend while I am there? I assume to make sure the impeller is even turning by running the engine with the cover off? Do I start to just pull hoses at various points along the circuit to see if water is flowing? Am I limited to buying an impeller puller or is there a cheaper tool I don't know about?

Any help isolating the problem would be appreciated. I hope I can get this done without paying someone to come out to the boat. I am willing to learn and do the hard work, but need some sage wisdom.

Thanks!

Labels:

Engine,

Inglis Weekends,

Saving Money

Subscribe to:

Posts (Atom)